- WhatsApp: +86 13390692151

- sale@kfqizhongji.com

- Mon - Sat 8:00 - 17:30, Sunday - CLOSED

-

Load Turning Device for Mining Dump Truck Bodies

-

10 Ton Capacity Turning Device for Overhead Cranes

-

Rotator Turning Device by Electric Motor

-

Belt Sling Rotators for Heavy Fabrication

-

Belt Single Sling Load Rotator

-

Load Turning Units for Irregular Workpieces

-

Turnover Spreader Beam with Electric Adjustable Units

-

Chassis Flip Device with PLC Control System

-

Electric Suspended Load Turner

-

Load Turning Units Suspended From Cranes

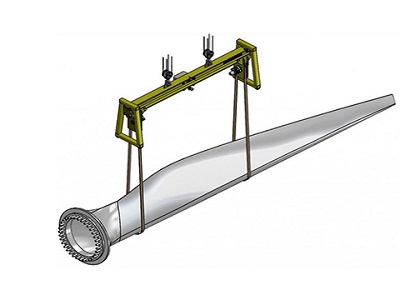

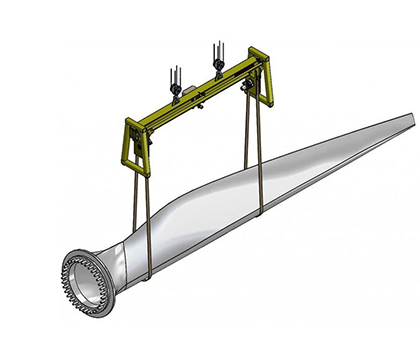

Wind Turbine Blade Lifting and Turning Device

Category: Load Turning Device

The lifting and turning device provides rotation and precise positioning solution for the assembly and maintenance of wind turbine blades, achieving 360° turning, automatic balance adjustment, and supporting customization.

Email:sale@kfqizhongji.com

Contact Us For QuotationThe lifting and turning device is a specialized tooling equipment designed specifically for the assembly, painting, inspection, and repair of wind turbine blades. It safely and smoothly lifts, horizontally rotation, and precisely positions blades in a controlled environment, significantly improving assembly efficiency, reducing manual labor risks, and minimizing damage to blades caused by secondary handling.

Functions and Benefits of the Lifting and Turning Device

● Optimized using finite element analysis, the main structure is constructed of high-strength alloy steel, ensuring safe handling of heavy loads.

● Electrically driven, it offers smooth tilting, with adjustable turning angles (0°–180° or continuously 360°) and support for locking at multiple positioning angles.

● Customizable automatic balancing ensures a stable turning process, preventing blades from slipping due to weight loss.

● Seamlessly integrates with workshop overhead cranes, enabling rapid transfer and turning of blades between workstations.

● Using polyurethane fiber belts for turning effectively protects blades from damage.

● We offer custom solutions tailored to your specific blade specifications, workshop layout, and process flow.

Typical Application Scenarios

● Blade factory assembly line

● Turning operations during painting/polishing

● On-site inspection and replacement

● Turning and positioning during blade storage and dispatch

● Quality inspection and non-destructive testing

Maintenance Recommendations

● Daily inspection: Check for wear on the turning mechanism, electrical wiring, and limit and emergency stop status.

● Regular maintenance: Lubricate bearings, inspect electrical components, and replace spare parts.

● Spare parts management: Maintain a stock of consumable parts (seals, gaskets, limit switches, sensors) to minimize downtime.

● Record management: Maintain maintenance logs and fault records for traceability and optimization.

If you're looking for solutions for the safe handling of wind turbine blades, contact our technical team today for free technical consultation and design services.

Customer Cases

Recommend News

- 2025-06-19 Operating Guide for Chain Load Turning Device in Foundry

- 2025-06-19 Rotating Lifting Beam for Flipping Loads

- 2025-11-11 Advantages of Belt Load Turning Device

- 2025-04-16 Rotating Lifting Equipment for Turning Heavy Loads

- 2025-11-11 Operation of Heavy Duty Car Frame Turning Device

- 2025-11-19 Can The Load Turning Units be Customized for Requirements

- 2026-01-27 Safely Rotating Large Machine Components with Turning Device

- 2025-09-08 Load Turning Units for Rotating Steel Structures

- 2024-12-27 What Are The Application Scenarios of Load Turning Devices

- 2025-01-21 Features of Truck Chassis Load Rotator