- WhatsApp: +86 13390692151

- sale@kfqizhongji.com

- Mon - Sat 8:00 - 17:30, Sunday - CLOSED

About Us

KUNFENG CRANES is a manufacturer specializing in the production and sale of bulky load turner, providing customers with free customized design solutions for turning devices.

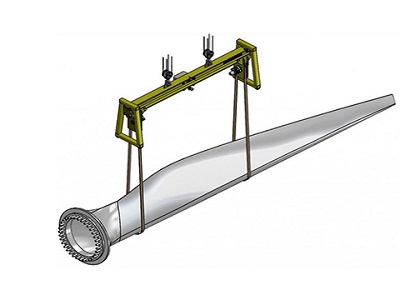

KUNFENG CRANES is a leading lifting equipment manufacturer in China, and the load turning device series is one of the company's core businesses. We focus on the research and development and manufacture of high-quality turning devices, mainly including chain load turning device, belt load turning units, chassis load rotator, turning device with automatic balancing functions, suspended lifting and rotating beam, etc.

The company's turning devices can be used in different scenarios, such as rotation of machine bodies, marine diesel engines, welding structures, moulding boxes for the foundry industry, large frames or chassis, etc. At the same time, we support customized production to meet the specific needs of customers, while focusing on product reliability, ease of operation and after-sales service to improve user experience and production efficiency.

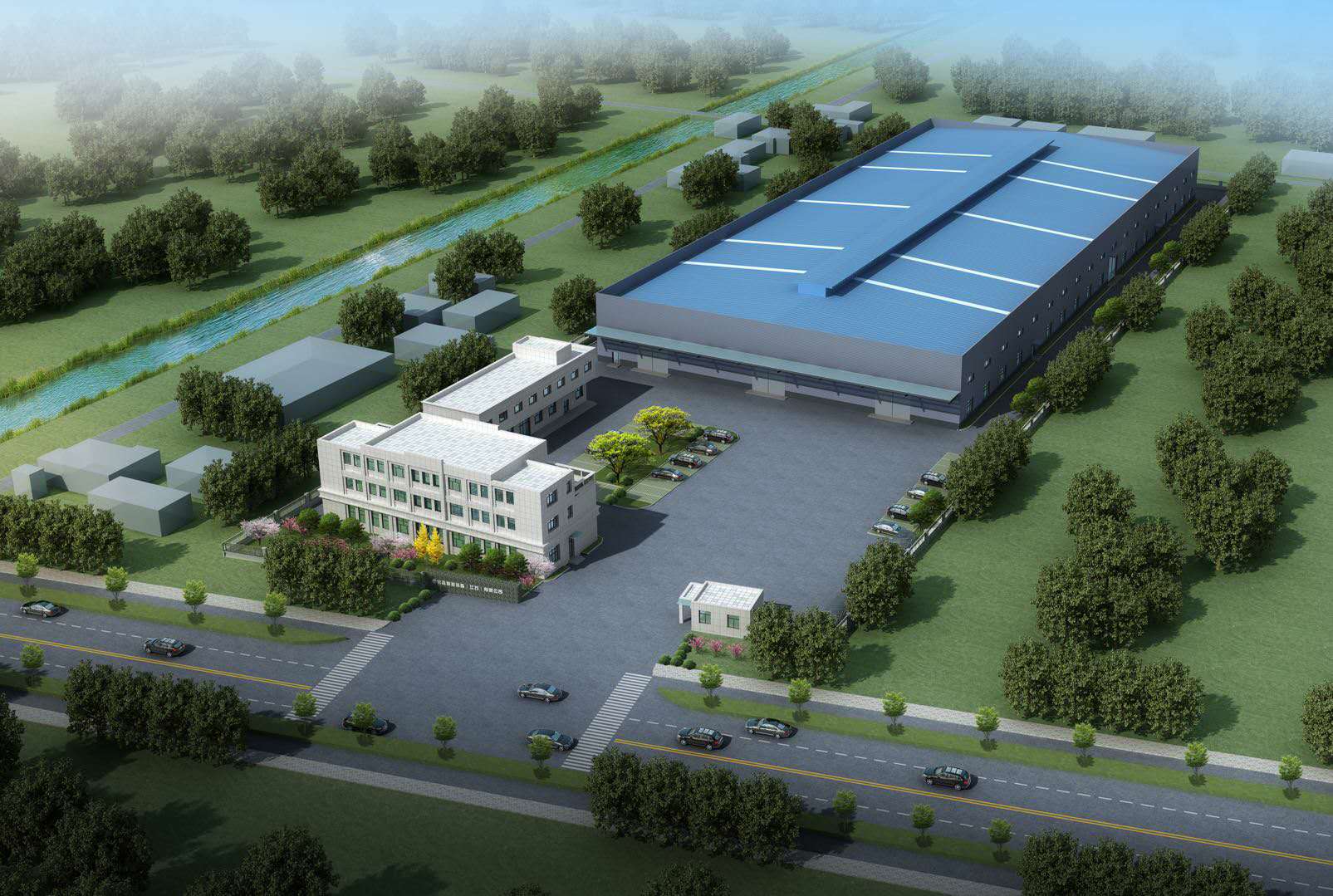

The company's headquarters is located in Suzhou, a scenic historical and cultural city. We have two major production bases: Dongtai Intelligent Material Handling System Production Base and Changshu Intelligent Three-dimensional Warehousing System Production Base, covering 40,000 square meters and 20,000 square meters respectively. The base has a modern standardized factory building, which is equipped with production and processing equipment such as laser cutting machines, 8-meter Haitian gantry milling machines, HNK vertical boring machines, Siemens CNC machining centers, and supporting laser trackers, three-coordinate and other testing equipment. Contact us for free design solutions and preferential prices!

Popular Products

Load Turning Device for Mining Dump Truck Bodies

KUNFENG load turning device enables the safe lifting and turning of truck bodies or materials, with load capacity ranging from 1 ton to 50 tons.

10 Ton Capacity Turning Device for Overhead Cranes

Our load turning device is designed to work in conjunction with overhead cranes, enabling smooth lifting and rotation of workpieces with load capacities ranging from 1 to 10 tons.

Rotator Turning Device by Electric Motor

The rotator turning device uses dual electric motor synchronous control, load capacity up to 50 tons. Smooth rotation and support wireless remote control operation.

Customer Cases

Hot News

- 2026-01-07 Rotation of The Weldment by Two Load Rotators

- 2025-10-10 Design of Double Chain Synchronous Drive Load Rotator

- 2025-01-02 What are The Types of Load Turning Device

- 2025-12-15 Belt Sling Rotator Turning Device for Rotating Steel Slab

- 2025-01-24 How to Keep Balance on Chain Turning Device

- 2025-04-16 Rotating Lifting Equipment for Turning Heavy Loads

- 2025-10-22 Turning Device of Loading and Rotating Conveyors

- 2025-11-11 Advantages of Belt Load Turning Device

- 2025-10-22 A Comprehensive Guide on How to Buy Rotator Turning Device

- 2025-06-19 Rotating Lifting Beam for Flipping Loads