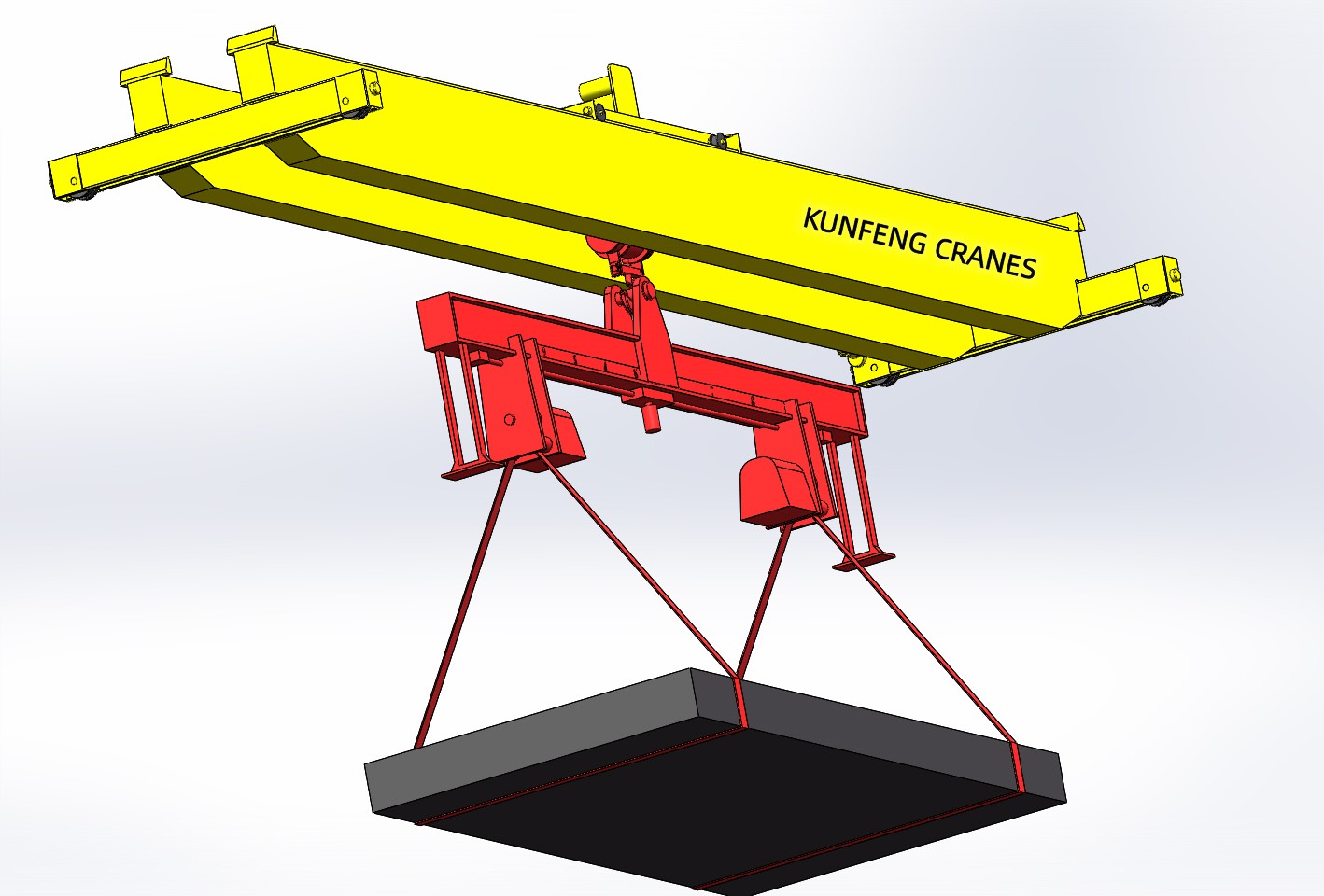

The belt sling rotator turning device adopts suspended mounting structure, combined with high-strength belt slings and electric drive unit, to achieve positioning and rotation at any angle from 0 - 360°. Effectively solves the challenges of steel plate welding, painting, assembly and transportation, key piece of equipment for improving steel plate processing efficiency and product quality.

The electric powered rotator turning device secures the steel slab on high-strength, wear-resistant belts by suspending it from both ends, while servo-driven motor drives the belt slings to perform controlled rotation. The rotation process supports continuous rotation or indexed positioning at specific angles (such as 90°, 180°, 360°) and can be integrated with overhead bridge crane or gantry crane to form a complete handling and turning system.

Advantages of the Rotator Turning Device

Suspended design, strong spatial adaptability

Electric drive, adjustable speed

Belt protection to protect the steel slab surface

Precise rotation, small positioning error

Smooth operation and even force distribution

Single-person remote control operation, improving efficiency

At a steel structure manufacturing plant in Argentina, we supplied a belt sling rotator turning device with rated capacity of 5 tons, which is used in conjunction with the existing overhead bridge crane for the turning and welding alignment of large steel slabs. After being put into operation, the steel slabs turning efficiency increased by approximately 40%, welding preparation time was significantly reduced, and thanks to the belt slings minimizing surface damage, the rework rate decreased noticeably.

The belt sling rotator turning device provides a reliable and efficient solution for processes such as steel plate handling, welding alignment and surface treatment. Click to contact us for free technical consultation and customized design solutions.